Understanding Control Transformers

Control transformers are essential components in various industrial and commercial applications, providing reliable and stable voltage regulation for control circuits. These transformers play a critical role in maintaining proper voltage levels to ensure the safe and efficient operation of control systems.

What is a Control Transformer?

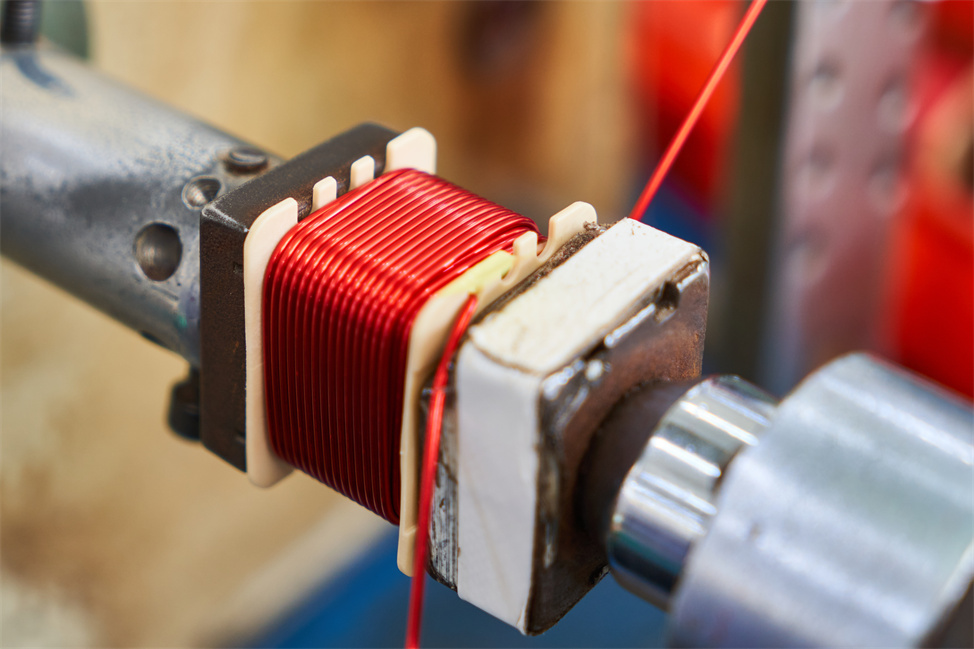

A control transformer, also known as an industrial control transformer or machine tool transformer, is a type of isolation transformer that produces significant secondary voltage stability during short periods of inrush current, also referred to as an 'overload condition.' This surge of abnormal current demand can be effectively managed by a control transformer, which provides excellent voltage regulation. These transformers are designed to ensure the stability and reliability of electrical systems by regulating the voltage supplied to control circuits.

Control transformers are renowned for their durable design, superior performance, and low maintenance requirements. They are widely used in various applications such as industrial automation, HVAC systems, motor control centers, renewable energy systems, power distribution panels, process control systems, motor starter buttons, and control room push buttons.

Key Differences Between Control and Power Transformers

One key distinction between a control transformer and a power transformer lies in their respective functions. A control transformer is primarily used to step up the voltage of low-voltage current to match application needs. In contrast, a power transformer is designed to step down the voltage of high-voltage current for specific applications.

Another notable difference is that while power transformers are primarily focused on transmitting electrical power from one circuit to another with minimal loss or distortion, control transformers are specifically tailored to provide precise voltage regulation for control circuits. This distinction underscores the specialized role that control transformers play in ensuring the efficient operation of electrical equipment across diverse industries.

The industrial control transformer market is projected to witness substantial growth in the coming years due to its wide-ranging applications across sectors such as manufacturing, processing, metals & mining, automotive industry, and more. The increasing demand for these transformers underscores their significance in powering instrumentation and control devices that monitor and regulate complex processes with high precision.

The Role of Control Transformers in Electrical Safety

Control transformers play a pivotal role in ensuring the safety and efficiency of electrical systems, particularly in industrial and commercial settings. Their ability to provide voltage regulation and handle momentary current inrush contributes significantly to the overall safety and reliability of control circuits.

Isolating Electrical Systems

Preventing Interference

One of the key functions of control transformers is to isolate electrical systems, preventing interference between different circuits. This is achieved by maintaining a stable output voltage, irrespective of potential variations in input voltage. By doing so, control transformers ensure that control circuits function reliably and accurately without being affected by fluctuations in the power supply.

Ensuring Safe Operation

Industrial control transformers are an excellent technology that prevents electrical accidents by providing steady output voltages within specified limits. This capability enables energy efficiency in industries while also reducing the risk of electrical hazards. Additionally, they are utilized in solenoids, relays, and electromagnetic devices, contributing to the safe operation of various electrical components.

Handling Momentary Current Inrush

Control transformers are designed to handle momentary current inrush effectively. When electromagnetic components are energized, there is a surge of abnormal current demand which can potentially disrupt the stability of the electrical system. However, with their impressive voltage control capabilities, control transformers mitigate energy spikes and ensure that control devices receive the required voltage for accurate operation.

Small Device, Big Impact: Exploring Control Transformer Applications emphasizes that voltage regulation refers to the ability of a control transformer to maintain a relatively constant output voltage despite changes in input voltage or load conditions. This ensures signal integrity and reliability within control circuits.

Enhancing Efficiency with Control Transformers

Control transformers play a crucial role in enhancing the efficiency of electrical systems by providing voltage regulation and converting high or low voltages to match application needs. This section will delve into the significance of voltage regulation and conversion, as well as identify signs of efficiency loss in control transformers.

Voltage Regulation and Conversion

Matching Application Needs

Efficient control transformers are designed to match the specific voltage requirements of diverse applications, ensuring optimal performance and reliability. By stepping up or stepping down voltages as needed, control transformers enable seamless integration with various control circuits, motors, and other electrical devices. This capability is essential for maintaining consistent operation across different industrial and commercial settings.

Ensuring Constant Voltage or Current

Industrial control transformers are known for their ability to ensure a constant voltage or current output, contributing to stable and reliable electrical systems. The precise regulation of voltage levels is critical for preventing equipment damage and optimizing the functionality of control circuits. By delivering a steady supply of power, control transformers facilitate smooth operations while minimizing the risk of power fluctuations that could compromise system performance.

In addition to these benefits, efficient control transformers experience fewer losses due to resistance, hysteresis, and other factors, which contributes to better voltage regulation. This capability enables them to maintain a relatively constant output voltage despite changes in input voltage or load conditions. As a result, they play a pivotal role in supporting energy-efficient practices within industrial processes.

Signs of Efficiency Loss in Control Transformers

Operating Temperature Increases

An increase in operating temperature can serve as an early indicator of efficiency loss in control transformers. When these components experience higher-than-normal temperatures during operation, it may signify issues such as increased resistance or inadequate cooling mechanisms. Monitoring temperature variations is essential for identifying potential efficiency concerns and addressing them promptly to prevent further deterioration.

Strange Noises

Unusual sounds emanating from a control transformer can also signal efficiency loss or underlying operational issues. These noises may indicate mechanical stress, loose connections, or internal component malfunctions that compromise the transformer's performance. Regular monitoring and prompt investigation of any abnormal sounds are crucial for maintaining the efficiency and reliability of control transformers within electrical systems.

Efficient control transformers are an excellent technology that prevents electrical accidents while enabling energy efficiency in industries. Their impressive voltage control capabilities make them indispensable for various uses and operations across industrial sectors such as manufacturing, processing, metals & mining, automotive industry, among others.

The need to reduce energy spikes in industries underscores the critical role played by efficient control transformers in ensuring stable power supply while minimizing disruptions caused by fluctuating voltages.

Applications of Control Transformers

Control transformers find extensive applications across diverse industrial and commercial settings, playing a pivotal role in ensuring the efficient and reliable operation of electrical systems. Their ability to provide voltage regulation and match specific application needs makes them indispensable components in various sectors.

Industrial Applications

In industrial settings, control transformers are widely utilized to power and regulate control circuits for a broad range of equipment and machinery. These transformers are integral to the smooth functioning of manufacturing processes, where precision control and stable voltage supply are essential. Industries such as automotive manufacturing, steel production, chemical processing, and heavy machinery rely on control transformers to ensure the safe and accurate operation of control systems.

Moreover, in the metals & mining industry, control transformers play a crucial role in powering conveyor belts, crushers, and other equipment that require precise voltage regulation for optimal performance. The robust design and exceptional voltage control capabilities of these transformers make them well-suited for handling the demanding operational requirements within mining facilities.

Commercial Applications

In commercial applications, control transformers are commonly employed in buildings and facilities to power HVAC (Heating, Ventilation, and Air Conditioning) systems, lighting controls, elevators, escalators, and security systems. These transformers contribute to energy efficiency by providing stable voltage levels for various building automation systems while minimizing the risk of electrical malfunctions or disruptions.

Furthermore, they are extensively used in retail environments to power automated doors, lighting controls, point-of-sale systems, and other electrical devices that require precise voltage regulation. The reliability and efficiency of control transformers make them essential components for maintaining seamless operations within commercial establishments.

The widespread adoption of control transformers across industrial and commercial applications underscores their significance in supporting critical operations while ensuring safety and energy efficiency.

Maintenance and Troubleshooting

Maintenance and troubleshooting are essential aspects of ensuring the optimal performance and longevity of control transformers. By identifying potential issues, conducting thorough inspections and testing, as well as implementing best practices for maintenance, organizations can mitigate operational disruptions and maintain the safety and efficiency of their electrical systems.

Identifying Potential Issues

Inspection and Testing

Regular inspection and testing are fundamental to identifying potential issues in control transformers. Visual inspections should encompass a comprehensive assessment of the transformer's physical condition, including signs of corrosion, overheating, or damage to insulation. Additionally, conducting routine electrical tests to measure voltage regulation and load capacity can reveal any deviations from expected performance levels. These proactive measures enable early detection of issues that could compromise the functionality of control transformers.

Common Problems and Solutions

Common problems encountered with control transformers include voltage fluctuations, overheating, insulation breakdown, and loose connections. Voltage fluctuations may result from inadequate regulation or external factors affecting the power supply. Overheating can be attributed to excessive loads or poor ventilation within the transformer enclosure. Insulation breakdown may occur due to environmental factors or aging components. Addressing these issues requires meticulous attention to detail and adherence to industry best practices for maintenance.

Implementing solutions such as recalibrating voltage settings, improving ventilation systems, replacing damaged insulation materials, and tightening connections can effectively resolve these common problems. Furthermore, regular cleaning of transformer components and ensuring proper grounding are crucial preventive measures that contribute to the long-term reliability of control transformers.

Best Practices for Maintenance

Maintaining control transformers involves adhering to best practices that promote their efficient operation while extending their service life. Implementing a structured maintenance schedule is paramount in ensuring that transformers receive timely attention and care. This includes periodic cleaning of internal components, inspection of wiring connections for signs of wear or corrosion, lubrication of moving parts if applicable, and monitoring temperature levels during operation.

Furthermore, organizations should prioritize staff training on proper handling procedures for control transformers, emphasizing safety protocols during maintenance activities. Establishing clear guidelines for reporting any irregularities or malfunctions observed during routine checks fosters a proactive approach to addressing potential issues before they escalate into critical failures.

Conducting regular performance assessments through load testing ensures that control transformers continue to meet specified voltage regulation requirements under varying operating conditions. Any deviations from expected performance parameters should prompt immediate investigation and corrective action to uphold the reliability of electrical systems.

Conclusion

Recap of Control Transformers' Importance

In conclusion, control transformers are indispensable electrical devices that play a critical role in ensuring the safety and efficiency of electrical systems across diverse industrial and commercial applications. These transformers are specifically designed to provide reliable and stable voltage regulation for control circuits, contributing to the smooth and accurate operation of various electrical components.

Logical Reasoning:

Control transformers are essential electrical devices used to provide reliable and stable voltage regulation for control circuits in various industrial and commercial applications.

Voltage regulation refers to the ability of a control transformer to maintain a relatively constant output voltage despite changes in the input voltage or load conditions.

Control transformers, also known as industrial control transformers or machine tool transformers, play a significant role across industries, providing reliable and efficient power management for control circuits.

Control transformers are generally used in an electronic circuit that requires constant voltage or constant current with a low power or volt-amp rating.

Industrial control transformers are an excellent technology that prevents electrical accidents. It is a crucial technology that enables energy efficiency in industries.

In summation, control transformers allow for low control circuit voltage to be safely used in applications where high voltages are required through the supply of control power.

Control transformers ensure that precise voltage levels are maintained within specified limits, enabling control devices to receive the required voltage for accurate operation. This capability is essential for preventing equipment damage and optimizing the functionality of control circuits while minimizing the risk of power fluctuations that could compromise system performance.

The significance of these transformers extends beyond their role in providing stable power supply. They also contribute to energy efficiency by facilitating precise voltage regulation, thereby minimizing disruptions caused by fluctuating voltages. This not only enhances operational reliability but also supports sustainable practices within industrial processes.

In summary, the widespread adoption of control transformers underscores their crucial role in supporting critical operations while ensuring safety and energy efficiency across industrial and commercial sectors. Their ability to regulate voltage effectively makes them indispensable components for maintaining optimal performance and longevity of electrical systems.

By understanding the importance of control transformers in isolating electrical systems, enhancing efficiency through voltage regulation and conversion, addressing potential issues through maintenance and troubleshooting practices, it becomes evident that these devices are fundamental for ensuring the safe and efficient operation of electrical systems.

In essence, control transformers stand as pillars of stability within complex electrical environments, safeguarding equipment from potential hazards while promoting energy-efficient practices across diverse industries.

Post time: Apr-26-2024